-

Pipe Fittings Seamless, Welded

-

Forged Fittings Socket weld, Threaded

-

Flanges Weld neck, Slip-on

-

Piping Spool Fabricated

-

Hot INDUCTION BEND Seamless, Welded

-

FLOW TEE Seamless, Welded

-

SPLIT TEE Seamless, Welded

-

BARRED TEE Seamless, Welded

Pipe Fitting

Elbow, Equal/ unequal Tee, Concentric/ Eccentric Reducers, Caps, Cross, Return Bend, Long Piggalbe Bends, 3D/5D/6D/8D upto 22D, S/J/U/ Expansion Bends & Swivels are manufactured according to ANSI B 16.9, B 16.28, MSS SP-43, MSS SP-95 & NACE etc.

Material Grades:

Carbon Steel : A234 WPB, WPC

Alloy Steel : A234 WP1, WP5, WP9, WP12, WP22, WP91

Stainless Steel : A403 304/L/H, 310/H, 316/L/H, 316Ti, 321/H, 347/H, 904L

Low Temperature Steel : A420 WPL6

High Yield : WPHY42, 52, 60, 67, 70

Copper Alloys : Copper, Cupro Nickel Brass, Gunmetal etc.

Nickel Alloys : 200, 400. K500, 600, 625, 800, 825

High Alloys : Alloy 20, Alloy C, Alloy C276, Alloy B2

Duplex & Super Duplex : A815 UNS31803, UNS31254, UNS S32750 & S32760

Size : ¼” NB TO 24” NB (above 24” NB two half Elbow upto 72” NB)

Our Products

Forged Fitting

Elbow, Tee, Union Cross, Coup Bushing, Plug, Swage Nipple, Welding Boss, Hexagon Nipple, Barrel Nipple, Welding Nipple, Parraler Nipple, Street Elbow, Hexagon Nuts, Hose Nipple, Bend, Adapter Insert, Weldolet, Elbowlet, Sockolet, Threadolet, Nipolet, Letrolet, etc.

Material Grades:

Carbon Steel : ASTM A105 / A694 F42/46/52/56/60/65/70/ A350 Lf2

Alloy Steel : ASTM A182 F1/F5/F11/F22/F91 etc.

Stainless Steel : ASTM A182 F304/304L/304H/316/317/317L/321/347/904L etc.

Other Monel, Nickel, Inconel, Hastalloy, Copper, Brass, Bronze, Titanium, Tantalum, Bismuth, Aluminum, High Speed Steel, Zinc, Lead, Etc.

Size : ¼” NB TO 4” NB. (Socketweld & Threaded)

Class : 3000#, 6000#, 9000#.

Our Products

Forged Fittings Socket weld, Threaded

Flanges

Weld neck, Slip-on, Blind, Socket Weld, Lap Joint, Spectacles, Ring Joint, Orific, Long Weld neck, Deck Flange etc

Material Grades:

Carbon Steel : ASTM A105 / A694 F42/46/52/56/60/65/70/ A350 Lf2, C22.8, etc.

Alloy Steel : ASTM A182 F1/F5/F11/F22/F91 etc.

Stainless Steel : ASTM A182 F304/304L/304H/316/317/317L/321/347/904L etc.

Other Monel, Nickel, Inconel, Hastalloy, Copper, Brass, Bronze, Titanium, Tantalum, Bismuth, Aluminum, High Speed Steel, Zinc, Lead, Etc.

Size : ¼” NB TO 24” NB. (above 24” as per customer requirement)

Class : 150#, 300#, 400#, 600#, 900#, 1500#, & 2500#.

Our Products

Flanges Forged, Plate

Piping Spool

A Pipe Spool is a prefabricated component of a piping system. Pipe Spools bolt up to flanges and connect these are often times used in big refineries connecting to ex-changers. Pipe Spools are made up of three components: Pipes, Flanges and Fittings. “During shut down in refinery, the already pre-fabricated spools are installed thus saving the time of the shut down.

Specifications:

Type : Fabricated

Size : 2” to 48”

Material : Carbon Steel, Alloy Steel, Stainless Steel.

Our Products

Piping Spool Welding,Threading

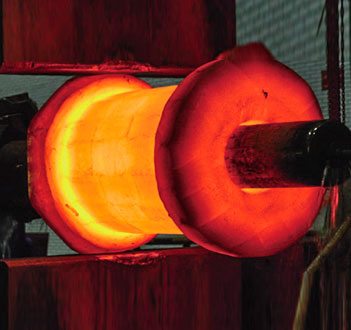

Hot INDUCTION BEND

Long Radius Piggable Bends are manufactured by hot induction bending method by uniform induction heating. These bends are used where there is need of passing pig through the pipeline, The bends are of long radius of curvature such as 5D, 6D etc. so that there is less Pipe Function & Flow is smoother for the pig to pass through the radius of the bends.

Specifications:

Type : Seamless/ Welded

Size : 2” to 24”

Material : Carbon Steel, Alloy Steel, Stainless Steel.

Our Products

Hot Induction Bend Seamless, Welded

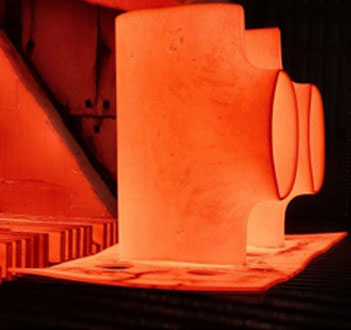

Flow Tee

The flow tee is a specialized fitting that facilities passage of pipeline pigs past tee connection where flow bypass often leaves pigs stranded, without restricting product flow.

The flow tee has an inner sleeve that directs the pig through the main line past the branch. Perforated holes on the sleeve and annular cavity provide a flow area at least equal to the flow area of the branch line, permitting full product flow through the tee during normal operation.

Specifications:

Type : Seamless/ Welded

Size : 4” to 48”

Material : Carbon Steel, Alloy Steel, Stainless Steel.

Our Products

Flow Tee Seamless, Welded

Split Tee

We offer Split Tee Fittings that handles both hot taps and line stops Compatible with existing hot tapping/plugging equipment, Eliminates piping alignment problems, no potential for weld to penetrate tapping area, allows for maximum hot tap size full range of reducing branch sizes available. Special Fitting available for any size, temperature, pressure, process or material.

Specifications:

Type : Seamless/ Welded

Schedule : Sch. 20 to XXS

Size : 2” to 18”

Material : Carbon Steel, Alloy Steel, Stainless Steel.

Our Products

Split Tee Seamless, Welded

Barred Tee

A barred tee is a tee or ant fitting with a branch used in pipelines that is pigged and has a restriction bar welded internally preventing the pig from traveling down a branch connection. The bars are installed so they are flash with the inside diameter of the pipeline to keep the pig from hanging up when it passes through. The bars should be of a similar or identical as the parent material.

Bars are placed on the internal side of the tee or really any branch connection big enough to sidetrack a pig while traveling down a pipeline. The size of the bars on the tee should be small enough so that they do not restrict the flow from the branch connection. However, they should be large enough to prevent breakage based on the flow rate though the branch connection of the tee.

Material Grades:

Size : 4” NB TO 42” NB. (Seamless & Welded)

Schedule : Sch. 5S to Sch. XXS

Carbon Steel : ASTM A234 WPB/ A429 WPL6/ MSS-SP75 WPHY 42/46/52/56/60/65/70

Alloy Steel : ASTM A234 WP1/WP5/WP9/WP22/WP91 etc.

Stainless Steel: A403 304/L/H, 310/H, 316/L/H, 316Ti, 321/H, 347/H, 904L

Our Products